On average, the production process for custom inflatables can take up to 30 business days, from quotation to shipping.

The table below lays out steps in the production process and how long each stage takes.

| Production Step | Business Days |

| Quotation | 1 |

| Conceptualization and modeling | 2–3 |

| Printing, assembly, and testing | 20 |

| Packaging and shipping | 4–6 |

| Total | 27–30 |

Source: MVP Visuals

Even then, other factors can influence this timeline like the complexity of your inflatable design.

In the following sections, we'll go over these steps in detail, with a focus on reducing production time.

Step 1 - The Quotation

Obtaining a quote kicks off your inflatable project and shouldn’t take you more than 24 hours.

It provides you with estimates to decide who to work with and gives the manufacturer the project’s scope.

From the quote, the manufacturer establishes the type and quantity of inflatables needed, their delivery dates, and their capacity to deliver.

An accurate and quick quote speeds up decision-making and is the first step towards optimizing production time.

Getting a Quick Quote

The crucial factor in a fast and accurate quote is response time. How available is the manufacturer for inquiries?

This is a typical issue for manufacturers who rely mainly on chatbots to answer customer inquiries.

While automation certainly improves response time, it isn’t always accurate; in which case, you’ll have to wait for a human response which can be slow for highly automated companies.

It’s no surprise that 86% of American consumers prefer human agents to chatbots.

Fortunately, some companies go to great lengths to ensure this human aspect.

MVP Visuals is a leading provider of custom inflatables and is committed to providing an excellent customer experience. Because we value your time, if you call during business hours and don’t speak to an actual person, you get a discount off your order.

Contact us at (800) 980-6871 and save time on your next inflatable project.

Step 2 - Conceptualization and Modeling

2D Model of a Custom Inflatable Tunnel

The conceptualization and modeling step takes up to three days and is crucial for capturing all the visual design elements of your custom inflatable like:

- Size and shape

- Brand logo placement

- Brand colors

- Specific artwork

It’s also necessary, from an engineering standpoint, to assess the practicality of your inflatable model. For instance, we look at airflow quality, stability, and resilience under different weather conditions.

In case of any engineering defects, the design team works with the client towards a better design, which shouldn’t take more than a day. Usually, defects require minor changes rather than abandoning the design and starting over.

Saving Time With Vector Files

During the modeling process, the vendor provides you with 2D and 3D mockups of your design with numerous editions with design variations based on your concepts.

This is where vector files speed up the design process.

Vector images are based on mathematical formulas and can therefore scale, at high-resolution, to virtually unlimited sizes.

Your logo on Instagram, saved in vector format, can resize to fit on a giant product replica or 15-foot inflatable arch without pixelation.

This feature eliminates the need for redesigning your images to scale (per pixel), saving time and associated costs.

Recommended Vector Format Options

- Encapsulated PostScript (.EPS): It’s an older vector file used to combine vector and raster files. However, it doesn’t support transparent backgrounds as modern vector files do.

- Adobe Illustrator (.AI): It’s the most common type of vector file used for editing. It can store large amounts of graphical information and be converted to .PDF for easy transfer.

- Portable Document Format (.PDF): This vector format is built to exchange documents between platforms. It’s also a standard format for most printers.

Step 3 - Printing, Assembly, and Testing

Actual production—printing, assembly, and testing—can take up to 20 business days or more for highly complex designs.

Meanwhile, simpler designs may take as little as 10 business days.

This difference comes down to the overall intensity of producing complex designs. There are more parts to assemble, materials to stitch, and artwork to incorporate and print.

The following table compares the production time of different inflatable projects manufactured by MVP Visuals.

| Type | Production Time |

| Inflatable arch | 2 weeks (10 business days) |

| Product replica | 3 weeks (15 business days) |

| Custom inflatable | 8 weeks (40 business days) |

Finding the Ideal Partner

Time efficiency relies on your vendor’s ability to meet deadlines and deliver on complex designs. Which is why you need to partner with an experienced manufacturer.

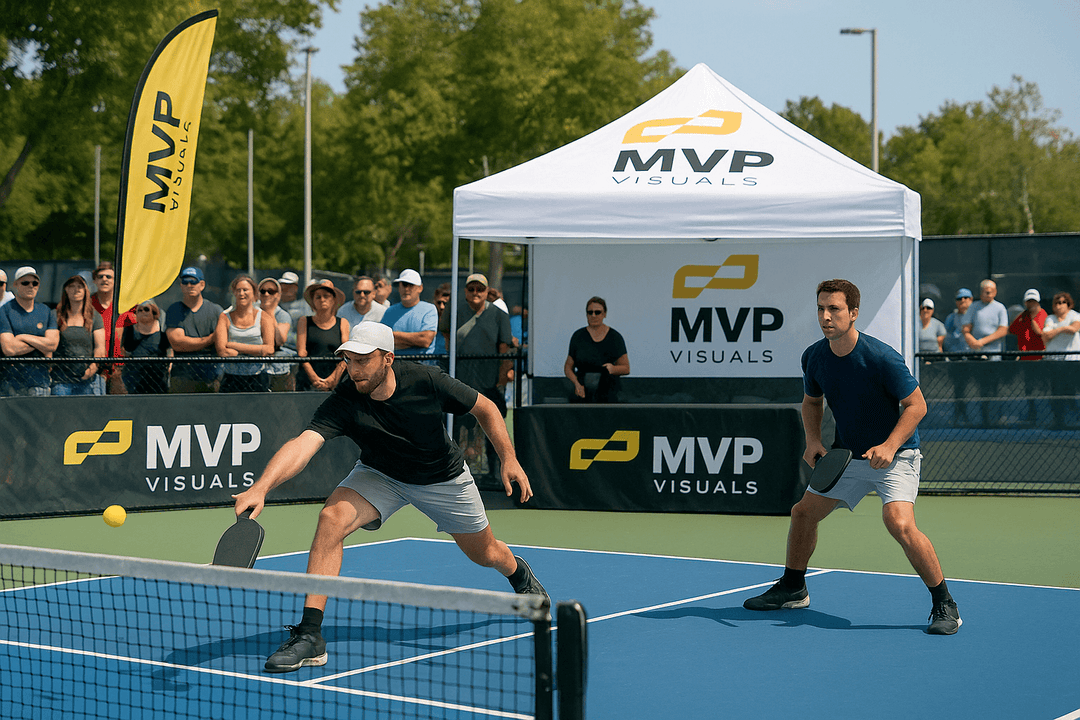

MVP Visuals has a wealth of experience with over 100,000 display items designed and delivered on time since 2006.

We’ve created custom inflatables for sporting brands, nonprofits, entertainment companies, and we guarantee prompt delivery.

If your inflatables are late, they're free and will be refunded within 24 hours.

Sign up today to learn more about our solutions for your next inflatable project.

Frequently Asked Questions

How long do inflatable mascot tunnels take to make?

Production of mascot tunnels takes about 15–20 business days (3–4 weeks). The tunnels are printed separately and come as attachments.

How long do samples take to ship?

At MVP Visuals, our samples ship within 24 hours and at no cost. We'll also send you confirmation of your sample request and tracking information.

The samples are usually sent during the conceptualization step to help you decide between customizable options like fabric or color.

Are custom inflatables made from scratch?

Yes. Unlike standard inflatables, custom inflatables are specially made according to a customer’s specifications.

Share on Facebook: